So I decided to pursue the ATX->Fuel conversion as well, with priceless of Pontus' and Recondas' research and diagrams, I can report success.

Oh, did I mention I met with Hamei 2 weeks ago for dinner and beers, he gave me his spare Fuel M/B - proved extremely useful for testing my ATX conversion

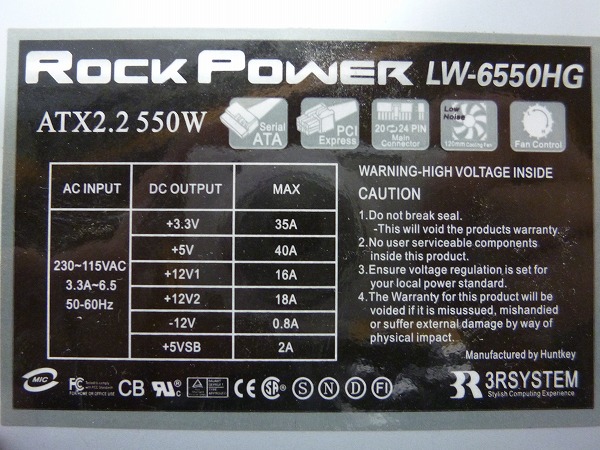

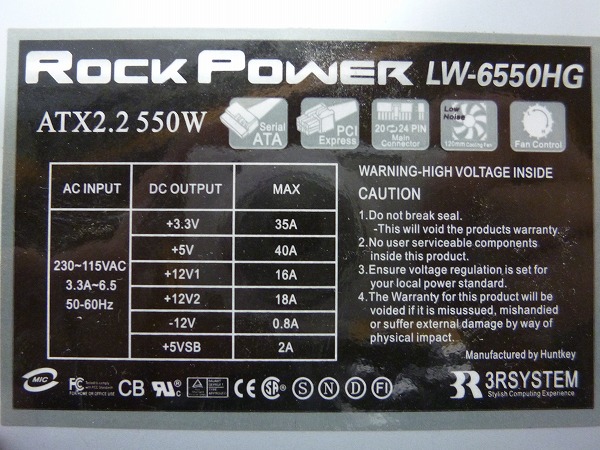

I got this:

RockPower 550W PSU, ATX2.2, model LW-6550HG (used for ~11$), and another AQTIS 600W AP-600GR (about the same price)

I decided to use the RP - since its power levels are much closer to my Fuel's NMB (lacks a little on the 3V3 and 5Vsb).

(NMB supplies: 27A on 5V, 16A on 12VIO, 18A on 12Vdig, 45A on 3.3V, 3A on 5Vsb, and 0.6A on -12V)

The PSU has 20+4 separable connector, 4-PIN 12V (P4 connector?), couple of HDD Molex, FDD, SATA, and 2x PCI-express.

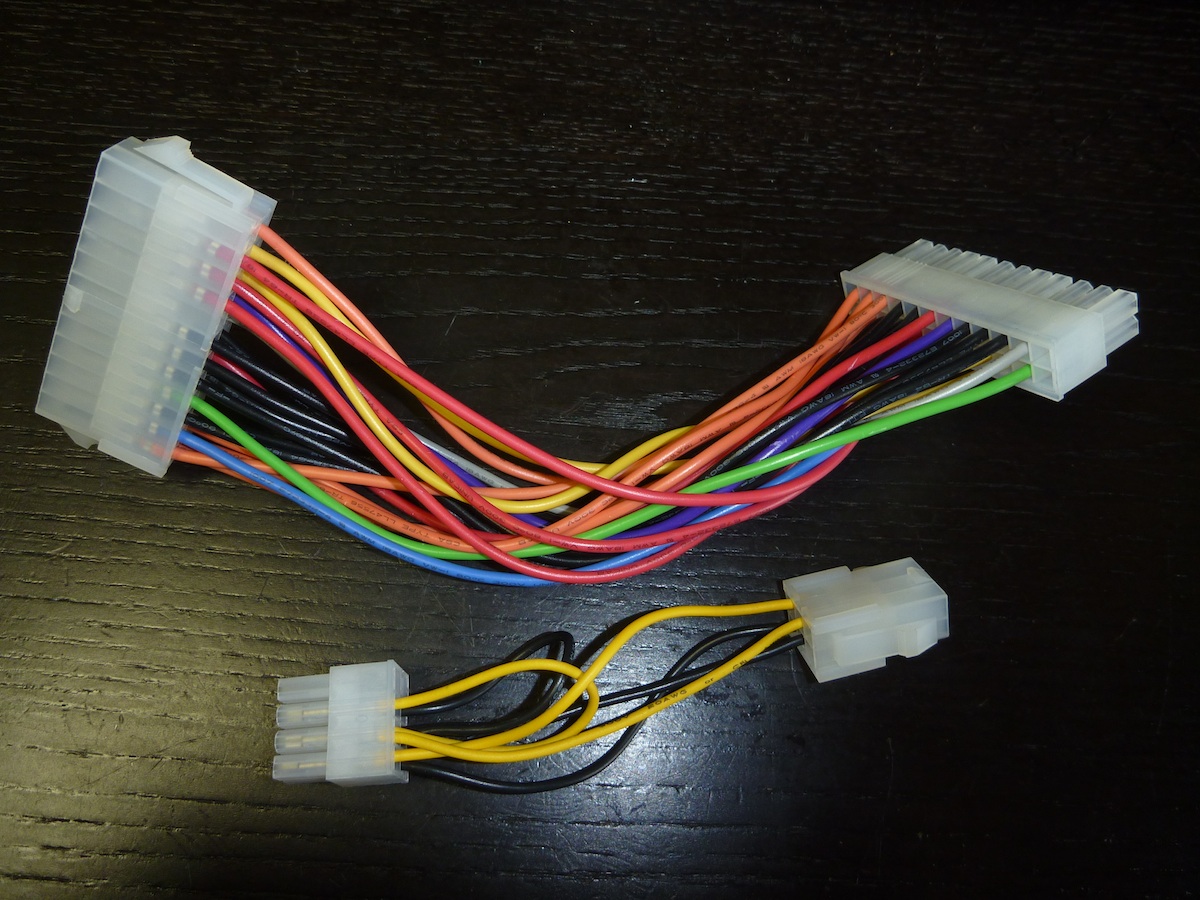

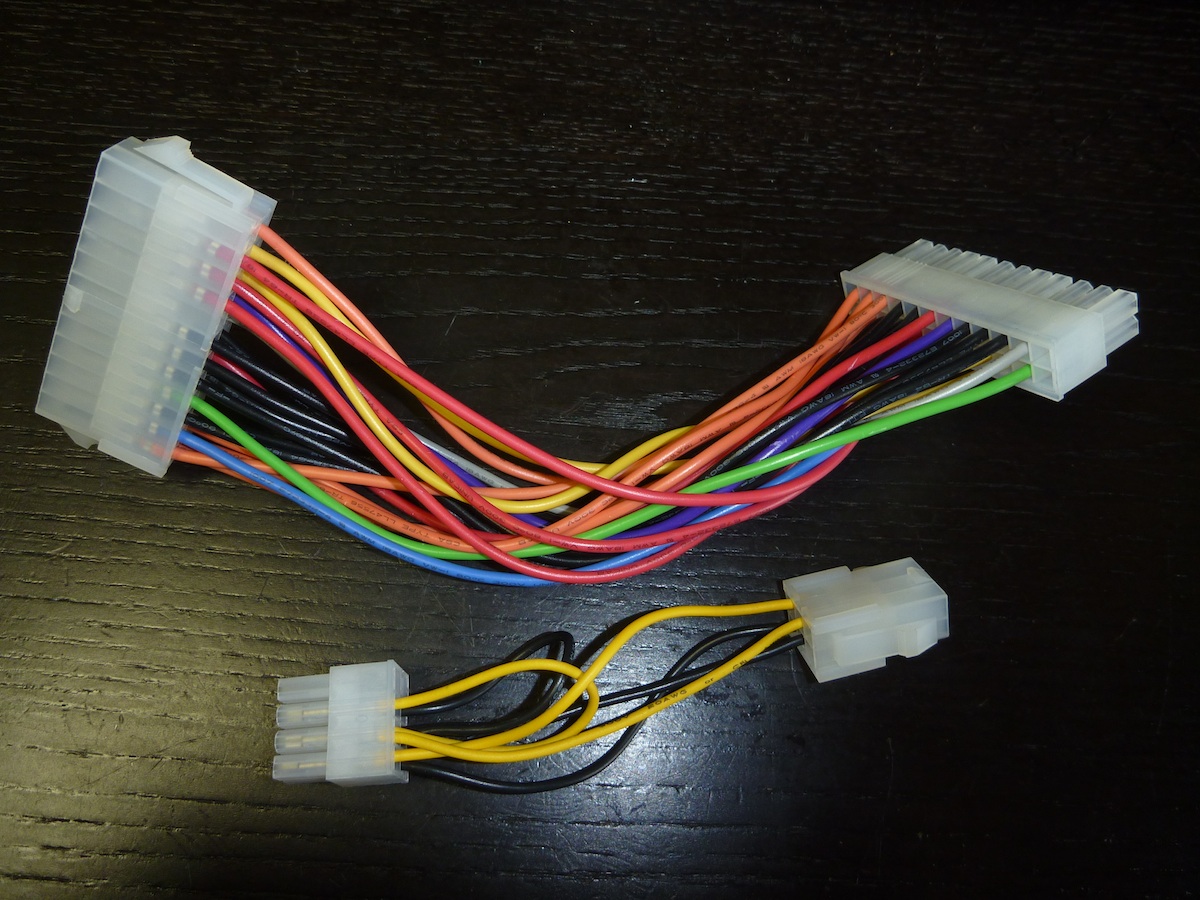

I also bought a few ATX 24-24 extenders, one ATX 24->20 and 20-24, and a few ATX 24 plugs/sockets with pins.

(hint - removing pins without real pin extractor (20$) takes a little practice, I found a sewing needle held tighly in the pliers to work well - wiggle here and there and it works)

Following my own research (looking at pins on the NMB), Recondas' diagram and Pontus' post as well - I've built conversion-extender for ATX.

Started with connecting all the GND pins, and 5VSB, checked L1 - it worked from the start.

As expected, only 5VSB and 3V3SB are available - since I connected only 5V, it means the MB is converting 5V to 3.3 (probably to power up all the env monitoring chips etc).

Code:

Select all

Connected.

ALERT: Unknown PSC: 15

INFO: Cannot disable power supply: 17

SGI SN1 L1 Controller

Firmware Image B: Rev. 1.10.12, Built 02/01/2002 14:40:22

001a01-L1>

001a01-L1>env

Environmental monitoring is enabled and running.

Description State Warning Limits Fault Limits Current

-------------- ---------- ----------------- ----------------- -------

12V Wait Pwr 10% 10.80/ 13.20 20% 9.60/ 14.40 0.13

12V IO Wait Pwr 10% 10.80/ 13.20 20% 9.60/ 14.40 0.13

5V Wait Pwr 10% 4.50/ 5.50 20% 4.00/ 6.00 0.00

3.3V Wait Pwr 10% 2.97/ 3.63 20% 2.64/ 3.96 0.29

2.5V Wait Pwr 10% 2.25/ 2.75 20% 2.00/ 3.00 0.00

1.5V Wait Pwr 10% 1.35/ 1.65 20% 1.20/ 1.80 0.00

5V aux Wait Pwr 10% 4.50/ 5.50 20% 4.00/ 6.00 5.10

3.3V aux Wait Pwr 10% 2.97/ 3.63 20% 2.64/ 3.96 3.29

PIMM0 12V bias Disabled 10% 10.80/ 13.20 20% 9.60/ 14.40 0.00

Asterix SRAM Wait Pwr 10% 2.25/ 2.75 20% 2.00/ 3.00 3.29

Asterix CPU Disabled 10% 0.00/ 0.00 20% 0.00/ 0.00 0.00

PIMM0 1.5V Disabled 10% 1.35/ 1.65 20% 1.20/ 1.80 0.00

PIMM0 3.3V aux Disabled 10% 2.97/ 3.63 20% 2.64/ 3.96 0.00

PIMM0 5V aux Disabled 10% 4.50/ 5.50 20% 4.00/ 6.00 0.00

XIO 12V bias Disabled 10% 10.80/ 13.20 20% 9.60/ 14.40 0.00

XIO 5V Disabled 10% 4.50/ 5.50 20% 4.00/ 6.00 0.00

XIO 2.5V Disabled 10% 2.25/ 2.75 20% 2.00/ 3.00 0.00

XIO 3.3V aux Disabled 10% 2.97/ 3.63 20% 2.64/ 3.96 0.00

Description State Warning RPM Current RPM

-------------- ---------- ----------- -----------

FAN 0 EXHAUST Wait Pwr 920 0

FAN 1 HD Wait Pwr 1560 0

FAN 2 PCI Wait Pwr 1120 0

FAN 3 XIO 1 Wait Pwr 1600 0

FAN 4 XIO 2 Wait Pwr 1600 0

FAN 5 PS Wait Pwr 1600 0

Advisory Critical Fault Current

Description State Temp Temp Temp Temp

-------------- ---------- -------- -------- -------- ---------

NODE 0 Wait Pwr 60C/140F 65C/149F 70C/158F 20c/ 68F

NODE 1 Wait Pwr 60C/140F 65C/149F 70C/158F 19c/ 66F

NODE 2 Wait Pwr 60C/140F 65C/149F 70C/158F 19c/ 66F

PIMM Disabled

ODYSSEY Disabled

BEDROCK Wait Pwr Not currently available

001a01-L1>

001a01-L1>fan

fan(s) are on.

fan 0 EXHAUST rpm 0 (255).

fan 1 HD rpm 0 (255).

fan 2 PCI rpm 0 (255).

fan 3 XIO 1 rpm 0 (255).

fan 4 XIO 2 rpm 0 (255).

fan 5 PS rpm 0 (255).

001a01-L1>serial

BSN: MEB034 SSN: 08:00:69:10:83:91 Time: 03/09/2012 20:47:22 CST

001a01-L1>serial all

Data Location Value

------------------------------ ------------ --------

Local System Serial Number EEPROM 08:00:69:10:83:91

Local Brick Serial Number EEPROM MEB034

Reference Brick Serial Number NVRAM NSR354

EEPROM Product Name Serial Part Number Rev T/W

---------- -------------- ---------- -------------------- --- ------

NODE IP34 MEB034 030_1707_003 F 00

MAC MAC ADDRESS NA NA NA NA

PIMM no hardware detected

XIO no hardware detected

EEPROM JEDEC Info Part Number Rev

---------- ------------------------ ------------------ ---

DIMM 0 no hardware detected

DIMM 2 no hardware detected

DIMM 1 no hardware detected

DIMM 3 no hardware detected

001a01-L1>

001a01-L1>power

Supply State Voltage Margin Value

-------------- ----- --------- ------- -----

12V off 0.125V N/A

12V IO NC 0.125V N/A

5V NC 0.000V N/A

3.3V NC 0.292V normal 0

2.5V off 0.000V normal 0

1.5V NC 0.000V normal 0

5V aux NC 5.096V N/A

3.3V aux NC 3.285V N/A

PIMM0 12V bias <not present>

Asterix SRAM NC ERROR (-204) normal ERROR (-207)

Asterix CPU <not present>

PIMM0 1.5V <not present>

PIMM0 3.3V aux <not present>

PIMM0 5V aux <not present>

XIO 12V bias <not present>

XIO 5V <not present>

XIO 2.5V <not present>

XIO 3.3V aux <not present>

Then I connected all the remaining pins except FANC and FANM - in my PSU the fan starts by itself (2PIN Molex).

Another test - (pwr up), the MB starts, reports some minor errors, then complains about fans - but the most important - all the voltages are very very good:

Code:

Select all

001a01-L1>power up

ERROR: I2C:not present

001a01-L1>

001a01-L1>

001a01-L1>

001a01-L1>env

Environmental monitoring is enabled and running.

Description State Warning Limits Fault Limits Current

-------------- ---------- ----------------- ----------------- -------

12V Enabled 10% 10.80/ 13.20 20% 9.60/ 14.40 11.94

12V IO Enabled 10% 10.80/ 13.20 20% 9.60/ 14.40 11.94

5V Enabled 10% 4.50/ 5.50 20% 4.00/ 6.00 5.12

3.3V Enabled 10% 2.97/ 3.63 20% 2.64/ 3.96 3.39

2.5V Enabled 10% 2.25/ 2.75 20% 2.00/ 3.00 2.47

1.5V Enabled 10% 1.35/ 1.65 20% 1.20/ 1.80 1.48

5V aux Enabled 10% 4.50/ 5.50 20% 4.00/ 6.00 5.10

3.3V aux Enabled 10% 2.97/ 3.63 20% 2.64/ 3.96 3.29

PIMM0 12V bias Disabled 10% 10.80/ 13.20 20% 9.60/ 14.40 0.00

Asterix SRAM Enabled 10% 2.25/ 2.75 20% 2.00/ 3.00 3.29

Asterix CPU Disabled 10% 0.00/ 0.00 20% 0.00/ 0.00 0.00

PIMM0 1.5V Disabled 10% 1.35/ 1.65 20% 1.20/ 1.80 0.00

PIMM0 3.3V aux Disabled 10% 2.97/ 3.63 20% 2.64/ 3.96 0.00

PIMM0 5V aux Disabled 10% 4.50/ 5.50 20% 4.00/ 6.00 0.00

XIO 12V bias Disabled 10% 10.80/ 13.20 20% 9.60/ 14.40 0.00

XIO 5V Disabled 10% 4.50/ 5.50 20% 4.00/ 6.00 0.00

XIO 2.5V Disabled 10% 2.25/ 2.75 20% 2.00/ 3.00 0.00

XIO 3.3V aux Disabled 10% 2.97/ 3.63 20% 2.64/ 3.96 0.00

Description State Warning RPM Current RPM

-------------- ---------- ----------- -----------

FAN 0 EXHAUST Active 920 0

FAN 1 HD Active 1560 0

FAN 2 PCI Active 1120 0

FAN 3 XIO 1 Active 1600 0

FAN 4 XIO 2 Active 1600 0

FAN 5 PS Active 1600 0

Advisory Critical Fault Current

Description State Temp Temp Temp Temp

-------------- ---------- -------- -------- -------- ---------

NODE 0 Enabled 60C/140F 65C/149F 70C/158F 20c/ 68F

NODE 1 Enabled 60C/140F 65C/149F 70C/158F 20c/ 68F

NODE 2 Enabled 60C/140F 65C/149F 70C/158F 20c/ 68F

PIMM Disabled

ODYSSEY Disabled

BEDROCK Enabled 60C/140F 65C/149F 70C/158F 21c/ 69F

001a01-L1>

001a01 ATTN: FAN 3 warning limit reached @ 0 RPM.

001a01 ATTN: FAN 3 fault limit reached @ 0 RPM.

001a01 ATTN: brick auto power down in 30 seconds

001a01 ATTN: brick auto power down in 25 seconds

001a01 ATTN: brick auto power down in 20 seconds

001a01 ATTN: brick auto power down in 15 seconds

001a01 ATTN: brick auto power down in 10 seconds

001a01 ATTN: brick auto power down in 5 seconds

001a01 ATTN: brick is powering down now!

001a01-L1>

If course this was still without RAM,PIMM, no fans etc.

It does complain about some I2C not present - I haven't figured that out yet.

Now - real-world test, I plugged the contraption to my Fuel - and voila, full success.

Code:

Select all

001a01-L1>env

************************************************

ATTENTION: Environmental monitoring is disabled!

************************************************

Description State Warning Limits Fault Limits Current

-------------- ---------- ----------------- ----------------- -------

12V Disabled 10% 10.80/ 13.20 20% 9.60/ 14.40 11.938

12V IO Disabled 10% 10.80/ 13.20 20% 9.60/ 14.40 12.063

5V Disabled 10% 4.50/ 5.50 20% 4.00/ 6.00 4.992

3.3V Disabled 10% 2.97/ 3.63 20% 2.64/ 3.96 3.320

2.5V Disabled 10% 2.25/ 2.75 20% 2.00/ 3.00 2.470

1.5V Disabled 10% 1.35/ 1.65 20% 1.20/ 1.80 1.466

5V AUX Disabled 10% 4.50/ 5.50 20% 4.00/ 6.00 5.018

3.3V AUX Disabled 10% 2.97/ 3.63 20% 2.64/ 3.96 3.268

PIMM 12V BIAS Disabled 10% 10.80/ 13.20 20% 9.60/ 14.40 12.063

SRAM Disabled 10% 2.25/ 2.75 20% 2.00/ 3.00 2.522

VCPU Disabled 10% 1.44/ 1.76 20% 1.28/ 1.92 1.622

PIMM 1.5V Disabled 10% 1.35/ 1.65 20% 1.20/ 1.80 1.495

PIMM 3.3V AUX Disabled 10% 2.97/ 3.63 20% 2.64/ 3.96 3.268

PIMM 5V AUX Disabled 10% 4.50/ 5.50 20% 4.00/ 6.00 5.018

XIO 12V BIAS Disabled 10% 10.80/ 13.20 20% 9.60/ 14.40 11.875

XIO 5V Disabled 10% 4.50/ 5.50 20% 4.00/ 6.00 4.992

XIO 2.5V Disabled 10% 2.25/ 2.75 20% 2.00/ 3.00 2.470

XIO 3.3V AUX Disabled 10% 2.97/ 3.63 20% 2.64/ 3.96 3.285

Description State Warning RPM Current RPM

--------------- ---------- ----------- -----------

FAN 0 EXHAUST Disabled 920 1163

FAN 1 HD Disabled 1560 2220

FAN 2 PCI Disabled 1120 1534

FAN 3 XIO 1 Disabled 1600 2250

FAN 4 XIO 2 Disabled 1600 2136

FAN 5 PS Disabled 1349 0

Advisory Critical Fault Current

Description State Temp Temp Temp Temp

----------------- ---------- --------- --------- --------- ---------

0 NODE 0 Enabled [Autofan Control] 80C/176F 22C/ 71F

1 NODE 1 Enabled [Autofan Control] 80C/176F 22C/ 71F

2 NODE 2 Enabled [Autofan Control] 80C/176F 20C/ 68F

3 PIMM Enabled [Autofan Control] 80C/176F 23C/ 73F

4 ODYSSEY Enabled [Autofan Control] 80C/176F 19C/ 66F

5 BEDROCK Enabled [Autofan Control] 85C/185F 22C/ 71F

************************************************

ATTENTION: Environmental monitoring is disabled!

************************************************

001a01-L1>

Note that I still have nothing under FANM and FANC - to make it run I had to disable env monitoring.

My ATX PSU's internal supervisor chip is sg6105dz, and this one doesn't seem to provide any FAN signal, nor does the FAN itself.

Now the next step for me, is to make up some square wave generator to fool the Fuel into thinking the signal is from real fan,

according to my research, it should be 50% duty cycle square wave, with 1 or 2 pulse per revolution (that depends on fan, I don't know which type is the original one - anyone ??) - if I want to report 2000 RPM (my original PSU reports 1900-ish) I need 2000 or 4000 Hz wave - that shouldn't be difficult, the only trick, is that signal needs to peak at 12V (nominal FAN supply), not sure how easy will it be to find a chip which does that.

Alternatively I could just buy a fan with tachyometer - but hey, that would be too easy

I might try to take the other ATX PSU apart and see it's fan - maybe that one has it available... (I didn't choose that PSU for Fuel since it supplies much less power on 3.3 and 5 - though it does supply a lot more on 12V). - it's most likely that new ATX12V standard.

And now mandatory picture of my conversion kit:

One thing I found very interesting, is that 5VSB in my NMB PSU is wired on the PCB to the 3V3 signal - but it DOES deliver 5V...

Cheers

<- MicroVAX 3500

<- MicroVAX 3500

<- MicroVAX 3300

<- MicroVAX 3300