vishnu wrote:

That's filmed in your shop?

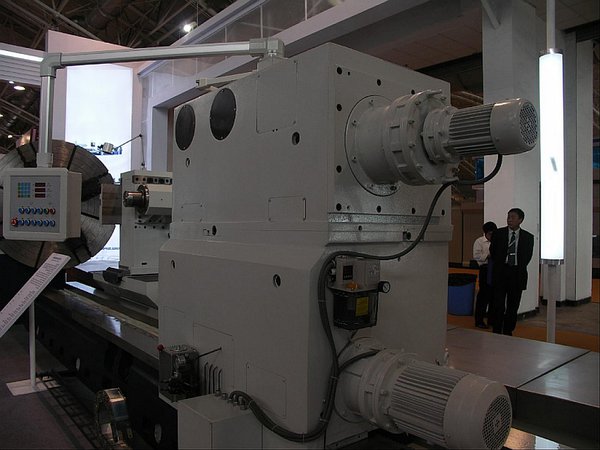

No, at Taylor-Winfield ...

Quote:

Cool!

Yes, they were. But since they couldn't return 30% per day on borrowed money and they had real assets, they are now just a gravestone to American capabilities.

Quote:

What's the video editor of choice on your

fool

? Or your o2...

I just do resizing, then cut and stitch pieces together. A few titles once in a while. Mencoder works pretty well for that kind of thing.

Quote:

for one they did not avail themselves of quick swap chuck technology,

They probably make different models. Does your purchasing agent know how to run a lathe ?

Quote:

it's almost impossible to put the thing in neutral! A millimeter off center and she creeps. Very annoying when you've got the chuck key in.

Once upon a time I was doing something on the Monarch when I hear this muffled gurgling clanking noise behind me. We had three Monarchs, my buddy liked the 17" MoriSeiki in the corner. When you hit the go lever it would shit-n-git. The go handle had this weird lockout on it that was a pain so the owner of the shop removed it. You know it's common to have all kinds fof crap sitting on the apron, Morg was tightening the jaws, a box of tool bits on the apron got knocked off, fell down onto the go handle in reverse, grabbed Morg and threw him over the top of the chuck into the chip pan headfirst. Luckily for him the jaws were only sticking out about an eighth inch, so there he was with his head in the chip pan gurgling, the chuck was wacking away at his belt buckle right near the family jewels, tick tick tick, and I was laughing my ass off.

I did turn the lathe off and rescue him.

Don't

ever

leave the chuck key in the chuck. It is not safe

Seriously, I know of another case where a guy had a chuck wrench slammed through his chest. He died. Bad idea to leave the key in, ever.

Quote:

And for a third the feeds and speeds placard is seemingly written in Egyptian hieroglyphics...

Take a photo, we can probably make you an rtf file that you could print onto some sticky paper to glue over the heiroglyphics. Of course, if we're feeling mischievous that day .....

R4600PC 133 MHz

R4600PC 133 MHz